Flight case hardware is the core of any durable and functional road case. Whether you’re building cases for musical equipment, AV systems, or industrial transport, choosing the right hardware parts is essential for strength, usability, and professional appearance.

In this guide, we break down the key types of flight case hardware and explain their roles—so you can make better sourcing decisions and improve your product line.

What Is Flight Case Hardware?

Flight case hardware includes all the metal components used to assemble, protect, and operate a road case. This covers:

- Handles

- Locks & latches

- Ball corners & stackable corners

- Hinges

- Aluminum extrusions

- Wheels and casters

- Corner braces & brackets

These parts are typically made from cold-rolled steel, zinc-plated or powder-coated for durability. Quality hardware helps cases survive harsh handling, frequent transport, and heavy loads.

1. Flight Case Handles

Handles are essential for safe and easy case transportation. The most common types include:

- Recessed handles: Sit flush with the surface. Great for stacking and protection.

- Surface-mount handles: Easy to install, good for lighter-duty cases.

- Spring-loaded handles: Return to flat position after use. Prevent snagging.

- Rubber grip handles: Offer extra comfort for frequent lifting.

✅ Tip: Choose heavy-duty handles with reinforced backing plates for large equipment cases.

At Guangzhou Lichuan Hardware, we offer OEM handle solutions with logo stamping, different coating options, and flexible MOQ.

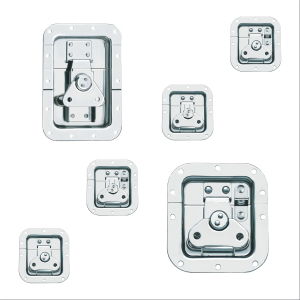

2. Butterfly Latches and Locks

Latches keep the case securely closed. Butterfly latches are industry standard for flight cases due to their strength and compact design.

- Standard butterfly latches: Strong and durable. Available in various depths.

- Pad-lockable latches: Add security for sensitive contents.

- Recessed latches: Protect against accidental opening and damage.

- Twist latches: Used in smaller or lighter cases.

Buyers often choose zinc-plated or black powder-coated versions to match their case style.

Lichuan Hardware supplies a wide range of latches, including custom mold development for your brand.

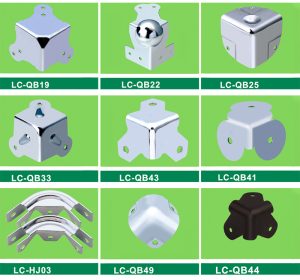

3. Ball Corners and Corner Brackets

Corners take the most hits during transport. Proper corner hardware protects edges and allows safe stacking.

- Steel ball corners: Most common for heavy-duty cases. Offer impact protection.

- Stackable corners: Allow cases to align when stacked.

- Flat corner brackets: Reinforce interior structure.

Look for corners with 2-leg, 3-leg, or flat designs depending on case structure.

✅ Pro tip: Use corner hardware with matching screw holes to simplify assembly.

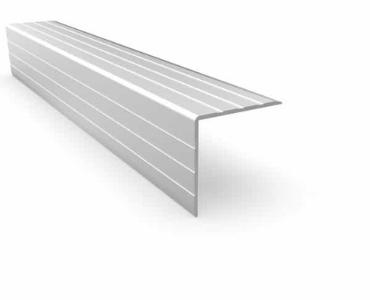

4. Aluminum Extrusions

Aluminum profiles give the flight case its frame. They are lightweight but strong, and help align panels during assembly.

- Single angle extrusion: Used for edges

- Double angle: For connections

- Lid-stay extrusions: Help align the lid perfectly

Lichuan offers aluminum profiles in custom lengths, anodized finishes, and with optional rubber seal strips.

5. Casters and Wheels

For large flight cases, wheels are non-negotiable. Look for:

- Swivel casters: For full mobility

- Braked casters: Add locking function for safety

- Heavy-duty casters: Load capacity of 100–300kg per wheel

- Blue elastic wheels: Smooth rolling, non-marking

We supply plate-mount and stem-mount types with steel or nylon cores, depending on your needs.

6. Hinges and Lid Stays

Hinges keep your case lid securely attached and ensure smooth opening and closing.

- Continuous hinges (piano hinges): For full-length support

- Butterfly hinges: Stylish and functional

- Lid-stay hinges: Hold lid at 90 degrees

For better protection, choose hinges with corrosion-resistant coatings.

Why Work with a Professional Flight Case Hardware Supplier?

Finding a full-range supplier helps reduce sourcing time and ensures product consistency. At Guangzhou Lichuan Hardware, we:

- Offer all hardware parts under one roof

- Support OEM & ODM customization

- Export globally with quality certifications

- Have our own factory: Foshan Kailis Metal Products

- Serve case manufacturers, brands, and distributors worldwide

Understanding each flight case hardware part helps you build stronger, smarter, and more functional cases. From handles to latches, corners to casters, each component plays a role in protection and usability.

If you’re a case builder, wholesaler, or brand looking for high-quality, customizable hardware parts, Lichuan Hardware is your trusted factory partner in China.