When it comes to flight case construction, choosing the right hardware is critical. Recessed latches are among the most essential components, providing a secure, low-profile locking mechanism that keeps contents safe during transit. In this guide, we explore the best recessed latches available, how they enhance flight case performance, and what to look for when sourcing from OEM and wholesale suppliers.

What Are Recessed Latches?

Recessed latches are flush-mounted locking devices commonly used in flight cases. Unlike surface latches, recessed models sit within the panel, reducing the risk of accidental impact and damage. These latches are ideal for road cases, AV equipment transport, and custom utility boxes.

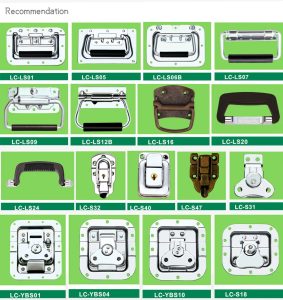

The most popular type is the butterfly latch, known for its reliability and compact design. Other options include draw latches, twist latches, and heavy-duty recessed padlocks. At our factory, we manufacture a wide range of recessed latches with OEM customization for different case types.

Why Recessed Latches Matter for Case Builders

Case builders know the importance of using durable, user-friendly components. Recessed latches not only offer superior protection but also create a sleek, professional look. They are preferred by industries like:

- Touring & Entertainment

- Audio/Visual Transport

- Aerospace & Defense

- Medical Equipment Mobility

- Industrial Equipment Storage

Proper latch selection helps minimize downtime and avoid damage to expensive gear. By sourcing high-quality recessed latches from trusted suppliers, case builders can meet performance demands and safety standards.

When selecting recessed latches for flight cases, consider these important factors:

- Material: Zinc-plated steel, stainless steel, and aluminum are common. Each has different strength and corrosion resistance.

- Mounting Style: Choose between rivet-in or screw-in models depending on your panel thickness.

- Locking Mechanism: Spring-loaded, twist-turn, or padlock-compatible designs offer different levels of security.

- Size and Profile: Slim, medium, and heavy-duty versions exist. Match the size to your case’s purpose.

- Finish: Powder-coated, brushed, or polished finishes improve durability and aesthetics.

Our company offers full customization on latch dimensions, finishes, and installation methods for wholesale orders.

Related Hardware for Flight Cases

Recessed latches work in combination with other components. At our China-based factory, we also manufacture:

- Flight Case Handles: Recessed pull handles, spring-loaded grips, and steel strap handles.

- Hinges: Detachable, piano-style, and surface-mount hinges to suit different access needs.

- Brackets: 2-hole and 4-hole braces for structural reinforcement.

- Corners: Rounded ball corners and flat corners for edge protection.

- Casters: Swivel wheels, brake-equipped casters, and heavy-duty base plates.

- Extrusions: Aluminum edge and tongue-and-groove extrusions for framing and sealing.

By sourcing all parts from one supplier, you ensure compatibility, reduce costs, and improve manufacturing efficiency.

OEM & Wholesale Services for Global Buyers

Our factory specializes in OEM flight case hardware solutions. We supply to distributors, case manufacturers, and repair shops worldwide. Services include:

- CAD-based product design support

- Custom branding and logo stamping

- Bulk production and stable lead times

- Strict quality inspection and packaging options

Whether you’re building touring cases in Germany, AV boxes in Canada, or medical transport units in Australia, we have the hardware solutions to match your needs.

Recessed latches are small components with a big impact. Choosing the right model ensures your flight case performs reliably, looks professional, and meets transport standards. By partnering with an experienced OEM hardware supplier, case builders gain access to quality components, customization flexibility, and consistent supply.

Explore our full catalog of flight case latches, handles, hinges, corners, casters, and aluminum extrusions today. We’re ready to support your next project.

For inquiries or custom requests, contact us directly. Let’s build durable, secure cases—together.